Electric Vehicles Are Noisy in Different Ways, and That's the Engineering Challenge

As modern cars become ever quieter, trading roaring V-8s and grumbling six-cylinders for muffled turbocharged small-displacement engines and near-silent electric motors, the cabin’s soundscape is now a mélange of small ticks and tones previously masked by combustion noise.

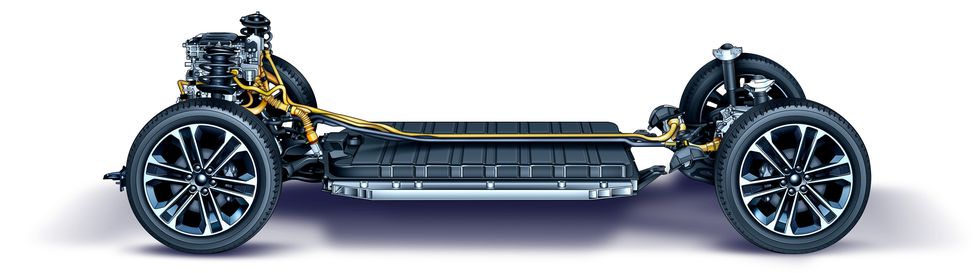

Without engine noise, electric vehicles don’t have much to hide ancillary rowdiness coming from climate-control fans, coolant systems, and tires. “There are no tricks: We need it all to be quieter,” says Tim Bohn, a noise, vibration, and harshness engineer at General Motors. “The levels from each subsystem have to be lower than we’ve ever had, especially in electric-vehicle cooling systems, where we now put much more effort into isolating coolant lines.” You might not think of cooling systems as noisy, but their hums, bubbles, and gurgles are a prime generator of uncouth acoustics.

It’s not just about making things quiet; it’s about making them the right kind of quiet. “You have to balance wind, road, and powertrain noise,” Bohn continues. “Those are the three fundamental tones the driver hears in the car, and the absence of any one of them is a little disconcerting.”

ILLUSTRATION BY JIM HATCH|Car and Driver

For example, drivers expect to hear something when mashing the accelerator, even in an EV. “EV drivers regularly tell us they want some type of feedback from the drive unit—they want to know the motor is working,” Bohn says. “Just like we used to do with exhaust manifolds and mufflers, we focus on the dominant motor tone and enhance it to produce the fundamental sound note for the automobile.”

What’s the Frequency, Kenneth?

Using mics to monitor cabin noise levels and then feeding inverted sound waves back toward the driver through the stereo system to “cancel” them works well for gas-powered vehicles but not so much for EVs. “This tech is limited to lower-frequency content, with an upper range of about 200 hertz,” says Bohn. Tonally, that’s roughly the same sound as tire drone. Bohn continues, “The problems in EVs start to show up around 500 to 600 hertz,” the frequency at which many EV components, such as gears and motors, resonate. Since engineers can’t cancel that sound, they have to dissipate it or tune it to be pleasant.

Making Weight

Electric vehicles are heavy, but that doesn’t mean they’re fat. To save weight, engineers have shifted away from additional sound deadening to dampen vibrations. “Every gram you put into a vehicle reduces range,” says Bohn.

ILLUSTRATION BY JIM HATCH|Car and Driver

Hear Ye, Hear Ye!

While some engineers are quieting the interior, others are working to make electric vehicles louder on the outside. Pedestrian-warning noises are federally mandated, and most brands are implementing similar motor whirs. This may spawn a new Grammy category.

Sound Design

Careful component design that includes optimizing materials and the methods used to fasten them together and mount them is critical to controlling noise, vibration, and harshness. A ground-up engineering approach can keep unwanted noise from ever entering the cabin. For example, the belly pans tucked under an EV’s drive unit channel noise away from the cabin interior.